Tech Report

Vertical blender/dryers deliver high drying rates with negligible risk of product attrition.

Technology Brief

Vertical blender/dryers designed for vacuum operation offer a better alternative to non-agitated dryers such as ovens and tray dryers, delivering significantly higher drying rates per unit heating area. Vertical blender/dryers can also handle a variety of feed forms including slurries and pastes which other types of agitated dryers cannot accommodate. Finally, the gentle mixing action supplied by a vertical blender/dryer minimizes product attrition which is a concern in some applications.

Agitated vs. non-agitated dryers

Agitated dryers give significantly higher drying rates per unit heating area than non-agitated systems such as ovens and tray dryers. This is due to continuous renewal of solids in contact with the dryer`s heated surfaces. In addition, the agitation improves uniformity of the product.

By contrast, due to long drying times, oven or tray drying operations are often allowed to proceed overnight which can impact energy costs and production rates.

The main issue with agitated dryers is the risk of product attrition or generation of too many "fines". Also, some designs, such as rotary dryers or tumble blenders, can typically accommodate only free-flowing solids as feed material.

Gentle blending, versatile performance

A vertical blender/dryer features a slow turning auger screw which orbits a conical vessel wall while it turns and gently lifts material upward. As materials reach the upper most level of the batch, they cascade slowly back down in regions opposite the moving auger screw. This blending action is almost always gentle enough even for the most delicate of applications, imparting significantly less shear than horizontally agitated systems, like ribbon or paddle-type blender/dryers.

Another advantage of the vertical blender/dryer is the wide range of feed forms that it can accommodate - from slurries, wet cakes and pastes, to granules, pellets and powders. Finally, vertical blender/dryers require a smaller footprint compared to other agitated dryer systems.

Benefits of vacuum drying

Requiring only low heat to drive off moisture or solvents, vacuum drying is an excellent method for drying heat-sensitive products without fear of thermal degradation. Drying is controlled and solvent recovery is efficient.

The application of a deep vacuum in combination with gentle heat and agitation in the vertical blender ensures short drying times. A liquid feed material, for example, will undergo a series of relatively swift changes in physical state – from slurry to a paste, and from a paste to a dry powder. Some applications such as plastics and specialty chemicals are commonly fed into the vertical blender already in solid form and may not look too different from the finished dried material.

Solvent recovery

A well-equipped vacuum drying system allows for solvent recovery. By condensing and capturing solvents, contamination of the atmosphere is prevented, both inside and outside the plant. They are then available for re-use or safely discarded to meet environmental requirements.

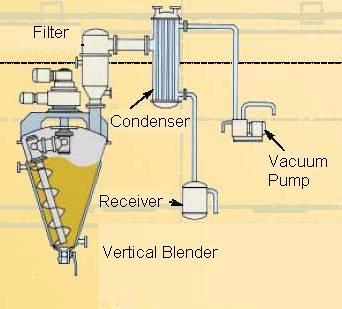

How a Vertical Blender/Dryer works:

Heat is applied to the jacketed vessel of the vertical blender. Once vacuum is established, the combination of low absolute pressure, gentle heat and slow agitation quickly forces moisture from the bulk material. The vapors generated in the process pass through a filter and into a condenser. A receiver collects the condensed liquids for re-use or proper waste disposal. At the end of the drying cycle, the finished product is discharged completely through the bottom valve of the vertical blender/dryer.

Sample Application: Dental Glass Powders

A manufacturer of dental products is using a 40-cu.ft. Ross Vertical Blender for preparing a blend of different silica powders.

All the raw materials are added to the pre-heated conical vessel. The blending and vacuum drying operation combined is completed in less than an hour, producing a homogenous blend and bringing down the moisture content from 1.5% to 0%.

The gentle blending action of the vertical blender is ideal for this abrasive application. As added protection against wear, the company chose to have the product-contacting moving parts of the blender to be hard-chrome plated. This includes the auger screw and outlet ball valve.

An important design feature standard on all Ross Vertical Blenders is the absence of a bottom support bearing. This facilitates complete discharge, simplifies cleaning and reduces contamination risks.