Tech Report

Ribbon blender do`s and don`ts

Technology Brief

This bulletin presents some ribbon blending tips to ensure long service life and produce consistent high quality blends.

Long-term relationship with your ribbon blender

Many solid-solid and liquid-solid applications rely on the ribbon blender for fast, straightforward and reliable mixing. The ribbon blender can achieve complete mixing in a short time - in many cases, 15 minutes or less - with little possibility of overmixing or unmixing, especially for ingredients with similar particle sizes and bulk densities. Operation is relatively easy and maintenance is minimal.

Indeed, a well-designed, well-specified ribbon blender operating under normal conditions can easily last 20, 30 years and beyond. To help ensure a long service life out of your capital investment and obtain high quality blends in every single batch, consider the following tips on ribbon blending.

Some do`s and don`ts to consider

- Do size your blender properly. The desired batch volume (not mass) determines the size of the ribbon blender but bulk density determines horsepower and if a standard or heavy-duty model is required. Industry-wide, most standard ribbon blenders can typically handle bulk densities of around 35 lb/cu ft. More robust blenders are available for products with higher bulk densities.

- Do not replace your existing ribbon blender`s motor with a larger one to handle a new higher-density formulation, at least not without consulting your blender manufacturer. The larger motor will not only increase the blender`s operating costs but can overpower the blender`s standard-duty agitator shaft and spokes. These components are typically designed to handle torque loading only up to a certain level and may bend, break, or fail mechanically when used with an oversized motor.

- Do use a variable frequency drive (VFD) to allow slow start under full load and protect the system against a spike in start-up torque. Electronic soft starters are also available but these allow only single speed operation during blending.

- Do not underfill your blender. Optimal mixing in a ribbon blender requires enough batch material - equivalent to at least 30-40% of the rated volumetric capacity. Working with smaller volumes, the blender fails to generate adequate contact between the agitator and the product.

- Do inform your blender supplier if you intend to remove the agitator after every batch. In most applications, there is no need to remove the agitator shaft when cleaning. However, some companies prefer to do so to eliminate cross-contamination of highly sensitive batches. To ensure proper alignment, simple customizations can be made, including match marks on the shaft flanges. More elaborate modifications allow operators to quickly raise the ribbon agitator out of the blender without moving the end shafts, bearings or seals.

- Do consider a paddle-style agitator instead of a ribbon if blending fragile materials. The ribbon agitator design inherently generates pinch points near the vessel walls wherein delicate product may be compressed or damaged due to high shear forces. The paddle agitator has less surface area at the periphery and imparts a gentler blending action.

- Do equip your ribbon blender with an extrusion screw if mixing thick pastes and other viscous applications. This screw enhances mixing and enables full discharge of the finished product.

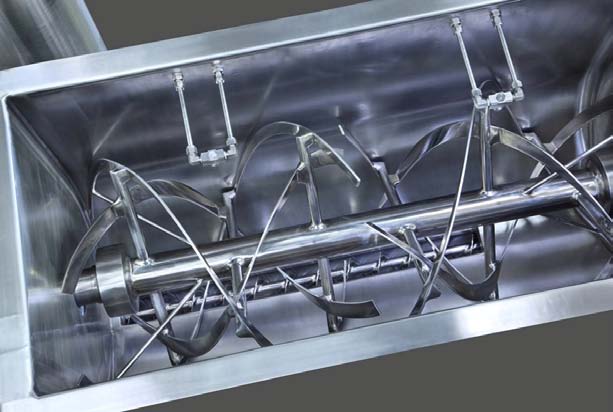

How ribbon blenders work

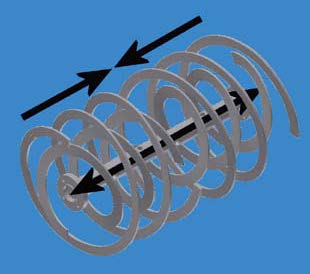

Ribbon blenders consist of a U-shaped horizontal trough and an agitator made up of inner and outer helical ribbons that are pitched to move material axially, in opposing directions, and also radially. This combination promotes fast and thorough blending. Tip speeds in the range of 300 feet/min are typical.

Sample Application: Ceramic Powders

A high-volume supplier to the steel industry is using a 385-cu.ft. Ross Ribbon Blender to blend magnesium oxide, silicon dioxide and other minor ingredients (binders, foaming agents, etc). The heavy-duty carbon steel ribbon blender is direct-driven by a 75HP motor and controlled via VFD. After the blending cycle, product is discharged through a 10" dust-tight knife gate valve and packaged in large super sacks for shipment to steel mills around the world. Users add water to the powders and the resulting slurry is sprayed to furnaces and tundishes. The slurry forms a disposable lining that extends the life of permanent refractories.