Tech Report

Recommended Mixing Equipment For Food and Drink Mixes

Application Summary

Many foods and beverages are supplied as dry mixes. It is a convenient form of delivering various products such as soups, sauces, protein supplements, smoothie recipes, cakes, muffins, breads and intermediate materials to end consumers, restaurants, bakeries and downstream food processing plants.

Product consistency relies on an efficient sanitary blending operation. Since dry mixes typically include additives, the blender must be capable of uniformly distributing minor ingredients throughout the batch to achieve the desired color, flavor, acidity, shelf life, flow characteristic and other properties.

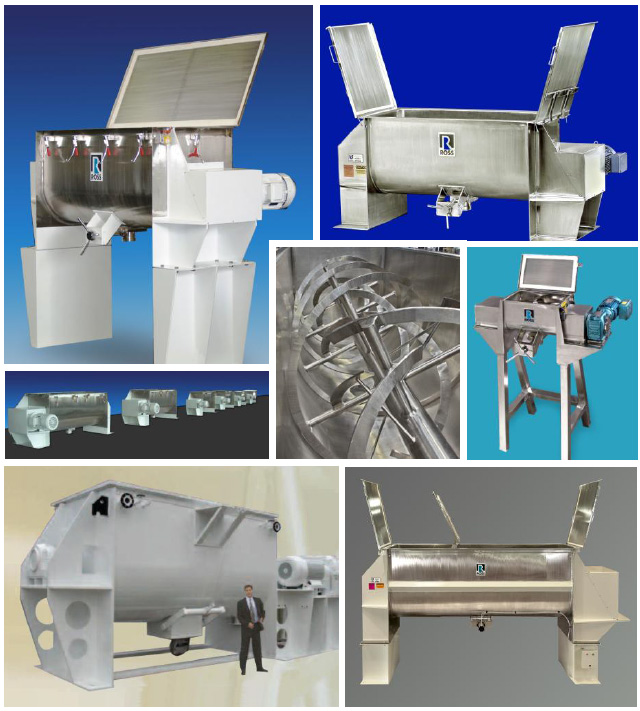

Ross Ribbon Blenders

The Ribbon Blender is well-proven technology for fast and cost-effective blending of bulk powders including food and drink mixes. Batch ingredients are mixed within a U-shaped trough via a horizontal agitator consisting of inner and outer helical ribbons. The position and precise pitch of both ribbons produce a well-balanced axial and radial flow pattern.

As the world`s largest manufacturer of Ribbon Blenders, Ross supplies hundreds of these blenders to food and beverage companies, flavor houses, toll manufacturers, commercial bakeries, gourmet food stores, food laboratories and raw material suppliers.

Other Food Applications produced in Ross Ribbon Blenders:

- Cake Batter

- Coffee Beans

- Dried Fruits

- Extruded Foods

- Flavorings

- Flours and Starches

- Food Additives

- Instant Coffee

- Petfood

- Canned Soups

- Sandwich Salads

- Seasonings

- Spices

- Sugar

- Sweeteners

- Tea Leaves

- Trail Mix Snacks

- Vitamins

Benefits of Ross Ribbon Blenders:

- Close tolerances between the outer ribbon and trough eliminate "dead zones" in the batch. Interior stainless steel surfaces are well-polished and each weld is "radiused" to prevent material buildup.

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike older belt-driven blenders which are noisy and prone to slippage, direct-driven Ribbon Blenders are more reliable and require less maintenance. These utilize compact gearmotors (one-piece motor reducers) which work well with inverters, so users benefit from electronic speed control, soft-start capability and overload protection.

- Different duty models are available for accurate sizing according to bulk density. Standard capacities range from 1/2 to 1,000 cu.ft.

- An interchangeable paddle agitator can be supplied for lower impact blending of friable ingredients.

- Customers rely on Ross for any customizations of their Ribbon Blenders: pneumatically operated covers, bag dump stations, special ports and discharge valves, liquid spray bar assembly, load cells, vacuum design, high speed choppers and PLC recipe systems, among others.