Tech Report

Recommended Mixing Equipment for Coffee Production

Application Summary

Most coffees consumed today are blends of different coffee varieties. Blending allows coffee producers to achieve consistent flavor, aroma, body, after taste and other qualities of their specific brand while having the flexibility to source beans from different suppliers and regions or during different seasons.

Proper blender selection is therefore a key consideration in coffee production. The ideal sanitary blender must be able to rapidly and cost-effectively mix different size coffee beans or ground particles and, if needed, evenly coat the solids with a liquid flavoring.

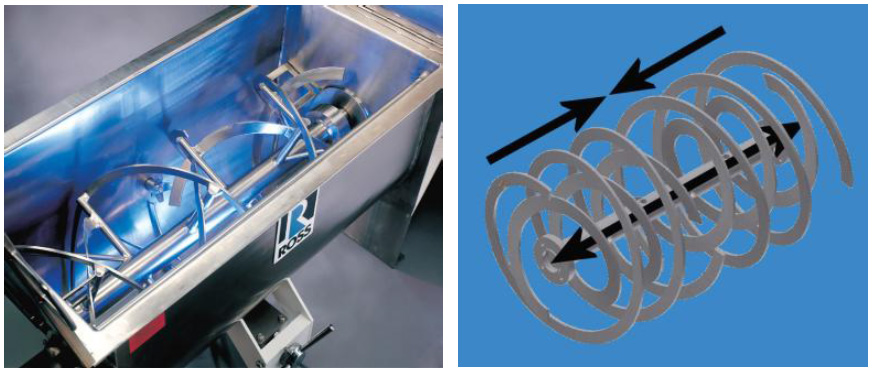

Ross Ribbon Blenders

Ross Ribbon Blenders are standard equipment used in the production of roasted coffee blends, instant coffee and other beverages. Ingredients are loaded into the U-shaped trough and mixed by a horizontal agitator consisting of inner and outer helical ribbons. The position and precise pitch of each ribbon produce a well-balanced axial and radial flow pattern which promotes fast and thorough mixing of different green (unroasted) or roasted whole coffee beans or ground coffee granules. Flavoring oils may be sprayed onto the coffee blend as the ribbons continue to agitate the batch, turning at tip speeds up to 300 ft/min. With variable speed control, the blending action can be fine-tuned and optimized according to the characteristics of a particular recipe.

Other Food Applications produced in Ross Ribbon Blenders:

- Cake Batter

- Coffee Beans

- Dried Fruits

- Extruded Foods

- Flavorings

- Flours and Starches

- Food Additives

- Instant Coffee

- Petfood

- Canned Soups

- Sandwich Salads

- Seasonings

- Spices

- Sugar

- Sweeteners

- Tea Leaves

- Trail Mix Snacks

- Vitamins

Advantages of Ross Ribbon Blenders:

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike older belt-driven blenders which are noisy and prone to slippage, direct-driven Ribbon Blenders are more reliable and require less maintenance. These utilize compact gearmotors (one-piece motor reducers) and inverters, providing electronic speed control, soft-start capability and overload protection.

- Different duty models are available for accurate sizing according to bulk density. Standard capacities range from 1/2 to 1,000 cu.ft.

- Ross Ribbon Blenders can be customized to include pneumatically operated covers, bag dump stations, special ports and discharge valves, interchangeable paddle agitator, liquid spray bar, load cells, PLC recipe systems and many other options.

- The outer ribbon and trough surfaces are normally built to very close tolerances in order to eliminate "dead zones" where product can collect. When blending whole coffee beans that are relatively large in size, tolerances can be modified to avoid damaging the beans. Very delicate batches may also be mixed in low shear, low speed equipment such as Ross Tumble Blenders and Vertical Blenders.