Tech Report

Recommended Mixing Equipment for Clay Dispersions

Application Summary

When suspended in liquid, certain clays provide bonding, plasticizing, thickening or suspending properties. They are used in a variety of products including pharmaceuticals, cosmetics, coatings, paints, adhesives, drilling fluids and other chemicals. Clays often require a dispersing agent in order to keep the slurry stable as long as possible. In addition, such mixtures are typically very process-dependent so that the mixing procedure and type of equipment employed directly impact the level of dispersion and stability. Manufacturers seeking to reduce production costs and improve end product quality cannot overlook the importance of proper mixer selection which could be just as critical as optimizing dispersant dosage or fine-tuning other components of the suspension.

Ross High Shear Mixers with SLIM Technology

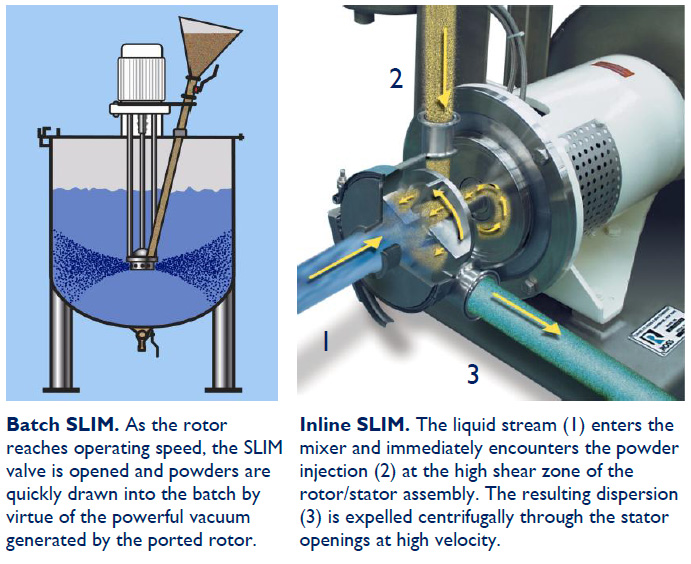

The Ross Solids/Liquid Injection Manifold (SLIM) Technology is proven to be extremely effective in the bulk mixing and dispersion of clay powders into water, oil, polymer, solvent or other liquid vehicle. This unique rotor/stator device creates a powerful vacuum for drawing and injecting solids to the liquid’s subsurface, at precisely the point where intense high-shear mixing takes place. By wetting out and dispersing clay powders through a SLIM mixer, manufacturers avoid typical processing headaches such as floating powders, dusting, lump formation and long cycle times.

The SLIM technology, available in both batch and inline designs, is simple to retrofit into almost any existing process. This system routinely handles solid loadings as high as 70%, depending on the application, while operating within a wide viscosity range: from water-like to up to 10,000 cP during powder injection. After all the solids are added, the operator may allow the product to continue to turnover as it thickens and until the desired level of dispersion is achieved. For instance, batch SLIM rotor/stators installed on Ross Multi-Shaft Mixers are utilized for suspensions that start out as thin slurries but finish with a final viscosity of several hundred thousand centipoise.

Processing advantages of the SLIM Technology

- Simple and straightforward operation. Just turn on the mixer and start inducting powders. No eductors or vacuum pumps to deal with.

- Easier material handling. The inline SLIM mixer is usually installed at floor level so operators no longer have to climb up mezzanines carrying heavy bags of powder. Solids can also be delivered via automatic feeding devices.

- Cleaner and safer mixing. A "hose & wand" attachment is used for dipping into bulk bags or containers to conveniently induct lightweight powders without creating a dusty environment.

- Increased yield and higher quality dispersions. By preventing the formation agglomerates and eliminating floating powders, the SLIM maximizes both yield and functionality of solid raw materials.

- Shorter cycle times. SLIM users report significant reductions in their overall mixing time, often by as much as 80% or more.

- Flexibility. The portable inline SLIM easily serves multiple process lines.