Tech Report

Recommended Mixing Equipment for Carbomers

Application Summary

Carbomers are water-soluble acrylic acid polymers available in dry powder form. Acting as thickening and gelling agents, different grades of carbomers produce a wide range of viscosities for suspending insoluble ingredients and stabilizing emulsions. They are widely used in cosmetics, personal care products and pharmaceuticals.

In most applications, only a small concentration of carbomer by weight is needed to achieve the desired viscosity profile but dispersing the low-density powder into water is often a processing challenge because of its tendency to float, foam and agglomerate. One proven solution that addresses all these issues is sub-surface powder injection as described in this bulletin.

Ross SLIM Technology

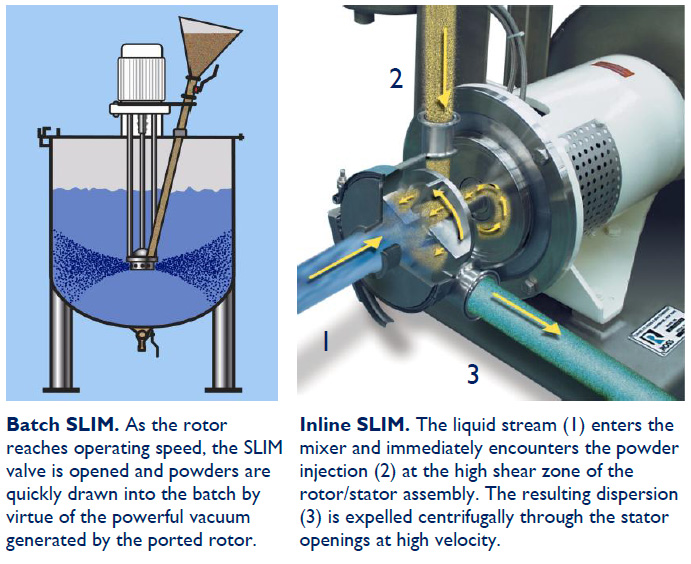

The Ross Solids/Liquid Injection Manifold (SLIM) Technology is well proven for rapid, high-volume dispersion of carbomers and other kinds of thickeners. The SLIM is a unique rotor/stator mixer capable of drawing and injecting powders directly into a high shear zone without the use of eductors or pumps. Its mixing action inherently generates a powerful vacuum that motivates solids sub-surface for immediate dispersion.

Small quantities of carbomer dispersions are typically prepared by sifting the powder and adding it carefully into an agitated liquid. This method minimizes agglomeration and floating powders but is too time-consuming and impractical for large-scale production. In comparison, the SLIM allows for fast sub-surface addition of carbomers while preventing the formation of lumps (partially hydrated polymers), excessive foaming and nuisance dusting. It combines the fine lightweight powders and liquid at precisely the point where vigorous mixing takes place. Particle wet-out is virtually instantaneous and because cycle time is very short, permanent viscosity loss due to over-mixing is easily avoided.

The SLIM Technology is available in both batch and inline designs, making it simple to retrofit into most existing processes. It can induct powders into any low-viscosity liquid below 10,000 centipoise (cP). After all the solids are wetted out, product viscosity may continue to increase as the carbomer particles continue to swell and hydrate. For formulations with a final viscosity (after addition of the neutralizing agent) of >100,000 cP, a Multi-Shaft Mixer with SLIM rotor/stator is recommended.

The Ross SLIM is proven technology for fast and efficient dispersion of many other solids including:

- Alginates

- Alumina

- Bentonite Clay

- Boric Acid

- Calcium Carbonate

- Carbomers

- Carbon Black

- Carrageenan Citric Acid

- CMC

- Dye Powders

- Ground Rubber

- Gum Arabic

- Magnesium Hydroxide

- Milk Powder

- Pectin

- Rosin Ester Resin

- Starch

- Sugar

- Talc

- Titanium dioxide

- Whey

- Xanthan Gum

Processing advantages of the SLIM Technology

- Simple and straightforward operation. Just turn on the mixer and start inducting powders. No eductors or vacuum pumps to deal with.

- Shorter cycle times. SLIM users switching from conventional mixers and stirrers report as much as 80% reduction in overall cycle time.

- Increased yield and higher quality dispersions. By preventing the formation agglomerates and eliminating floating powders, the SLIM maximizes both yield and functionality of raw materials.

- Easier material handling. The Inline SLIM is usually installed at floor level so operators need not climb up a mezzanine carrying heavy bags of powder. Solids can also be delivered via automatic feeding devices.

- Cleaner and safer mixing. A "hose & wand" attachment is used for dipping into bulk bags or containers to conveniently induct lightweight powders without creating a dusty environment.

- Flexibility. The Inline SLIM can be supplied on a mobile cart to serve virtually any size vessel located anywhere in the plant.