Tech Report

Recommended Mixing Equipment for Body Washes and Shower Gels

Application Summary

This bulletin discusses the benefits of high-speed, high-shear powder injection in the manufacture of body washes, shower gels, liquid hand soaps, facial cleansers and other similar personal care products. Such technology, like theRoss Solids/Liquid InjectionManifold (SLIM), can be applied to almost any existing mixing setup - an upgrade that entails very little reorganization. It offers significant production gains by improving throughput and dispersion quality while reducing foaming, dusting and waste.

Ross High Shear Mixers with SLIM Technology

Powder dispersion is an important step in the production of body washes, shower gels, hand soaps, shampoos, lotions, aftershaves and other personal care products.Traditionally used turbine mixers and paddle agitators unfortunately often suffer from inefficiencies related to slow wet-out and incomplete dissolution. Once challenging powders form agglomerates or "fish eyes," it is very difficult and time consuming to break them apart. Manufacturers resort to filtering out these lumps or devoting separate mixing tanks for certain powders. These solutions however negatively impact production costs and maintenance requirements.

A better processing method is achieved by systems like the Ross Solids/LiquidInjection Manifold (SLIM), a new generation rotor/stator mixer designed for rapid addition of powders without subsequent lumping. This technology combines solids and liquids at precisely the point where intense mixing takes place such that agglomerates are prevented from forming in the first place. Powders like xanthan gum, carbomers, guar, cellulose gum (CMC), gum Arabic, aloe vera, citric acid and titanium dioxide are quickly dispersed or solubilized due to the SLIM`s unique mechanism of injecting powders sub-surface right into a high shear zone. It can dramatically reduce cycle time from several hours to mere minutes, improving not only process efficiency but also product quality.

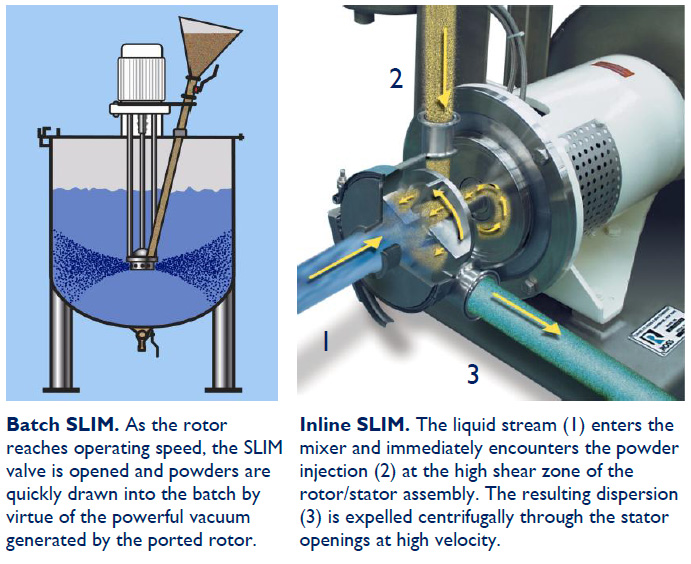

Oils, fragrances, colorings and other liquid additions can also be done through theSLIM. Available in both batch and inline designs, it is simple to retrofit into most existing processes. One common set-up is to install the inline SLIM mixer in are circulation loop connected to the main blending tank or kettle. Another option is the batch-style SLIM rotor/stator as part of a multi-agitator mixer - an ideal configuration for viscous products and intermediates above 20,000 centipoise.

The Ross SLIM is a proven technology for fast and efficient dispersion of many raw materials including:

- Alginates

- Alumina

- Bentonite Clay

- Boric Acid

- Calcium Carbonate

- Carbomers

- Carbon Black

- Carrageenan Citric Acid

- CMC

- Dye Powders

- Ground Rubber

- Gum Arabic

- Magnesium Hydroxide

- Milk Powder

- Pectin

- Rosin Ester Resin

- Starch

- Sugar

- Talc

- Titanium dioxide

- Whey

- Xanthan Gum

Processing advantages of the SLIM Technology

- Shorter cycle times. SLIM users report significant reductions in their overall mixing time, often by as much as 80% or more.

- Simple and straightforward operation. Just turn on the mixer and start inducting powders. No eductors or vacuum pumps to deal with.

- Increased yield and higher quality dispersions. By preventing the formation agglomerates and eliminating floating powders, the SLIM maximizes both yield and functionality of solid raw materials.

- Narrower particle size distribution. Improved mixing performance leads to smoother texture, better stability and extended shelf life.

- Fewer processing problems. SLIM users benefit from reduced foaming and dusting in the plant. In most cases, this method of high-speed powder injection renders pre-mixing in separate tanks unnecessary thereby eliminating or reducing transfer steps, contamination risks and bottlenecks.

- Flexibility. The portable inline SLIM unit can be used in multiple process lines virtually regardless of vessel size or shape.