Tech Report

Recommended Mixing Equipment For Alginates

Application Summary

Alginates are gelling, thickening and stabilizing agents used in a wide range of products. Extracted from the cell walls of brown algae, alginates are available in powdered and granular forms which absorb water to form a viscous gum.

Various grades of alginates pose a mixing challenge due to their tendency to agglomerate. Slow and careful addition into liquid helps to minimize lumping but can become impractical in large-scale production and cause serious process bottlenecks. Vigorous mixing is usually required to effectively hydrate individual alginate particles. At the same time, the resulting solution must not be over-sheared to avoid permanent loss of viscosity.

Ross SLIM Technology

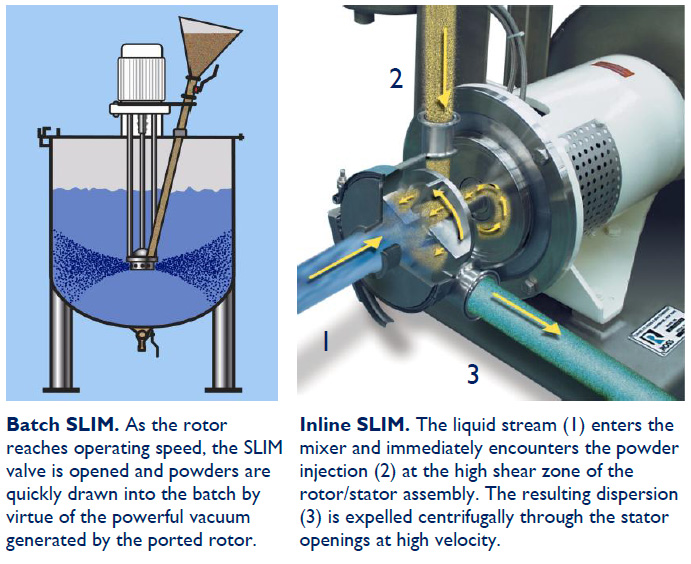

The Ross Solids/Liquid Injection Manifold (SLIM) Technology is well proven for fast dispersion of alginates as well as other kinds of gums and thickeners. The SLIM is a unique rotor/stator mixer designed to create a powerful vacuum that draws and injects powders directly into a high shear mixing zone.

In conventional batch mixing systems, alginate powders are slowly added into the vortex of a vigorously agitated liquid batch. This minimizes agglomeration and in some cases, the alginate is first combined with other dry ingredients to further improve the dispersion quality. Even then, prolonged mixing is sometimes necessary to ensure complete hydration but over-shearing the gum can lead to viscosity loss or degradation due to excessive heat. By comparison, the SLIM enables rapid addition of alginates without subsequent lumping. It combines solids and liquids sub-surface at precisely the point where intense mixing takes place. The formation of lumps and "fish eyes" is greatly reduced, if not eliminated. Dispersion is virtually instantaneous and as a result of the shorter cycle time, alginate solutions and other sensitive dispersions are less prone to being overworked.

The SLIM technology is available in both batch and inline designs, making it simple to retrofit into most existing processes. During powder injection, liquid viscosity could be water-like or as high as 10,000 cP. After all the solids are added, product viscosity may continue to climb. For instance, a batch-style SLIM rotor/stator installed on a Ross Multi-Shaft Mixer can be used for batching formulations with a final viscosity of several hundred thousand centipoise.

The Ross SLIM is proven technology for fast and efficient dispersion of many other solids including:

- Alumina

- Bentonite Clay

- Boric Acid

- Calcium Carbonate

- Carbomers

- Carbon Black

- Carrageenan

- Citric Acid

- Dye Powders

- Ground Rubber

- Guar

- Gum Arabic

- Hydroxyethyl Cellulose

- Magnesium Hydroxide

- Milk

- Pectin

- Starch

- Talc

- Titanium dioxide

- Whey

- Xanthan Gum

Processing advantages of the SLIM Technology

- Simple and straightforward operation. Just turn on the mixer and start inducting powders. No eductors or vacuum pumps to deal with.

- Shorter cycle times. SLIM users report significant reductions in their overall mixing time, often by as much as 80% or more.

- Increased yield and higher quality dispersions. By preventing the formation agglomerates and eliminating floating powders, the SLIM maximizes both yield and functionality of solid raw materials.

- Easier material handling. The inline SLIM mixer is usually installed at floor level so operators no longer have to climb up mezzanines carrying heavy bags of powder. Solids can also be delivered via automatic feeding devices.

- Cleaner and safer mixing. A "hose & wand" attachment is used for dipping into bulk bags or containers to conveniently induct lightweight powders without creating a dusty environment.

- Flexibility. A portable SLIM unit can be used in multiple process lines serving mix vessels of various sizes.