Tech Report

Recommended Equipment for Dry Blending of Polymers and Additives

Application Summary

Polymer additives such as lubricants, UV and heat stabilizers, colorants, preservatives, flame retardants and impact modifiers are commonly supplied as dry powders or pellets which are blended with virgin plastic feedstock prior to compounding. Thorough and accurate mixing is necessary to achieve a consistent finished product.

Proper blender selection is a therefore a key consideration in plastics production. A well-designed ribbon blender, for instance, can rapidly mix different solids of varying shapes, particle sizes and densities, can be cleaned easily and accommodate fast product changeovers.

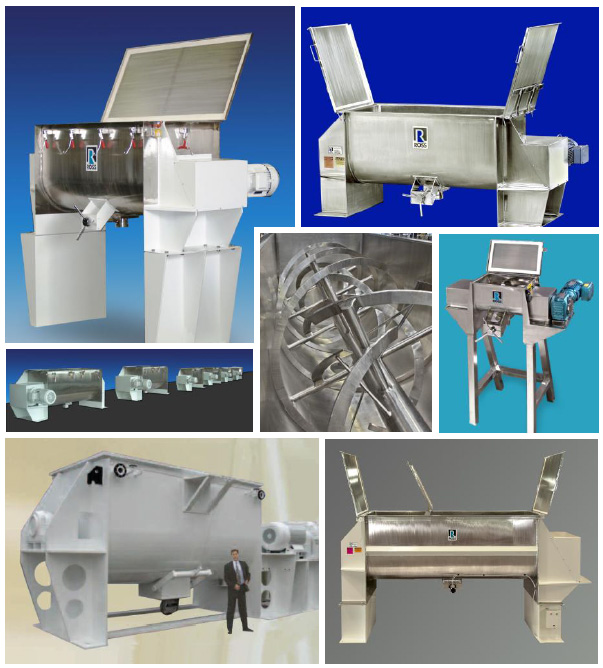

Ross Ribbon Blenders

Ross Ribbon Blenders are proven equipment used in the processing of plastics, particularly for dry blending polymer pellets or beads with solid additives. Ingredients are loaded into the U-shaped trough and mixed by a horizontal solid-shaft agitator consisting of inner and outer helical ribbons. A full load usually corresponds to a product level around the outer ribbon`s tip, allowing enough headroom for the materials to be vigorously agitated.

The position and precise pitch of each ribbon produce a well-balanced axial and radial flow pattern, promoting fast and thorough mixing despite differences in particle shape, size and density. Maximum tip speeds in the neighborhood of 300 ft/min are typical but with variable speed control, the blending action can be fine-tuned and optimized according to the characteristics of a particular recipe.

Ross Ribbon Blenders are fabricated to close tolerances for accurate mixing. Clearances between the agitator and the trough surfaces typically fall within the 1/8" to 3/16" range. This enhances mixing performance by preventing batch materials from stagnating in any part of the blender during the mix cycle.

Other Applications of Ross Ribbon Blenders:

- Advanced Ceramics

- Animal Feeds

- Baking Pre-mixes

- Chemicals

- Coffee Beans

- Cosmetic Powders

- Dental Powders

- Detergents

- Drink Mixes

- Flavorings

- Glass

- Metal Powders

- Pesticides

- Pharmaceuticals

- Refractory Powders

- Soups

- Spices

- Sugars and Sweeteners

- Trail Mix Snacks

- Vitamin Supplements

Advantages of Ross Ribbon Blenders:

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike belt-driven blenders which are noisy and prone to slippage, direct-driven Ribbon Blenders are more reliable and require less maintenance. The cost-effective and space-saving combination of a gearmotor (one-piece motor reducer) and a variable frequency inverter delivers electronic speed control, soft-start capability and overload protection.

- Interior stainless steel surfaces are polished and each weld is "radiused" for easy cleanability. In addition to tightly-controlled clearances between the agitator and trough, end wall scrapers can be supplied for highly sensitive applications to further prevent "dead zones" where product can collect.

- Different duty models are available for accurate sizing according to average bulk density. Standard capacities range from 1/2 to 1,000 cu.ft.

- Ross Ribbon Blenders can be customized to incorporate pneumatically-operated covers and discharge valves, bag dump stations, custom ports, interchangeable paddle agitator, liquid spray bar, load cells, high speed choppers, rotary CIP spray balls, PLC recipe systems and other accessories to help ensure streamlined ingredient transfers, efficient discharge and fast changeovers.