Tech Report

Recommended Blending Equipment for Seasonings

Application Summary

Thorough mixing in a well-designed Ribbon Blender is an ideal method for preparing seasonings, spices and herbs with batch-to-batch consistency.

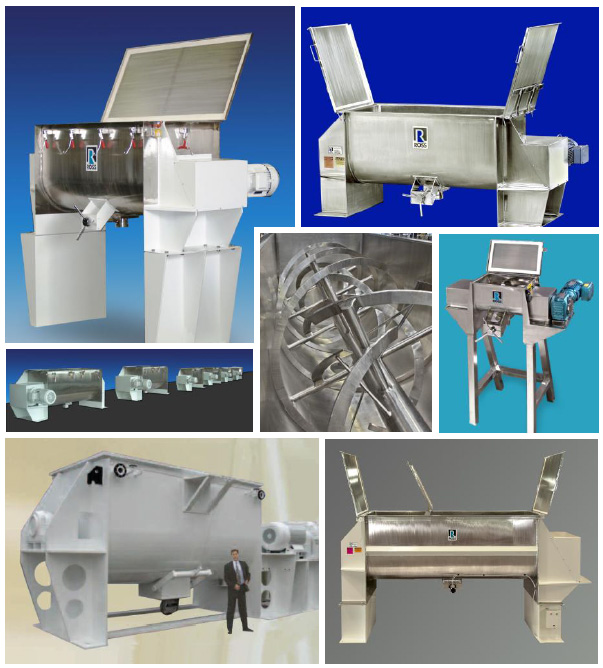

Ross Ribbon Blenders

Many food manufacturers, flavor houses and toll blending companies rely on Ross Ribbon Blenders for their seasonings, spices and herb mixes. Dry ingredients are loaded into a U-shaped trough and mixed by a horizontal agitator consisting of inner and outer helical ribbons. Liquid additions are made by pouring or spraying into the batch as the agitator is running. The position and precise pitch of each ribbon produce a well-balanced axial and radial flow pattern, promoting fast and thorough mixing.

Maximum tip speeds are approximately 300 ft/min but with variable speed control, the blending action can be fine-tuned and optimized according to the characteristics of a particular recipe. Ground spices like cinnamon, cloves and ginger benefit from high rpm, short duration blending cycles. More fragile blends containing whole spices and leaves may require gentler mixing. In addition to speed control, a Ross Ribbon Blender can be equipped with an interchangeable paddle agitator to maximize the range of shear input.

In many plants, the multi-purpose Ross Ribbon Blender is not only used for seasonings and spices but also other blends like powdered beverages, sweeteners, baking pre-mixes, flavors, coffee, food additives and trail mixes. Even "wet" products like soups, cake batter and sandwich salads are also prepared in Ross Ribbon Blenders. This machine is easy to clean and wash down so product changeovers are quick and operator-friendly.

Other Applications of Ross Ribbon Blenders:

- Ceramic Powders

- Baking Pre-mixes

- Chemicals

- Coffee Beans

- Cosmetic Powders

- Dental Powders

- Detergents

- Drink Mixes

- Flavorings

- Glass

- Metal Powders

- Pesticides

- Pharmaceuticals

- Refractory Powders

- Soups

- Spices

- Sugars and Sweeteners

- Trail Mix Snacks

- Vitamin Supplements

Advantages of Ross Ribbon Blenders:

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike belt and chain-driven blenders which are noisy and prone to slippage, direct-drive Ribbon Blenders are more reliable and require less maintenance. The cost-effective and space-saving combination of a gearmotor (one-piece motor reducer) and a variable frequency inverter delivers electronic speed control, soft-start capability and overload protection.

- Certified by the Baking Industry Sanitation Standards Committee (BISSC).

- Interior stainless steel surfaces are polished and each weld is "radiused" for easy cleanability. In addition to tightly-controlled clearances between the agitator and trough, end wall scrapers can be supplied to further prevent product from collecting in certain areas.

- Different duty models are available for accurate sizing according to bulk density. Standard capacities range from 1/2 to 1,000 cu.ft.

- Ross Ribbon Blenders can be customized to incorporate pneumatically-operated covers and discharge valves, bag dump stations, custom ports, interchangeable paddle agitator, spray bar assembly, end wall scrapers, lantern rings, bottom discharge extruder, sanitary features, heating/cooling jacket, load cells and other options to help ensure streamlined processing and fast changeovers.