Tech Report

Recommended Blending Equipment for Feeds and Fertilizers

Application Summary

Animal feeds and fertilizers require blending of different granules, prills or powders and sometimes spraying of a liquid component such as a vitamin slurry, oil, active ingredient solution or other minor additive. Thorough coating of the dry solid particles and accurate mixing is necessary to achieve a consistently homogenous finished product with the desired composition levels. Blender selection and specification is therefore a critical step when establishing a suitable process or upgrading an existing one.

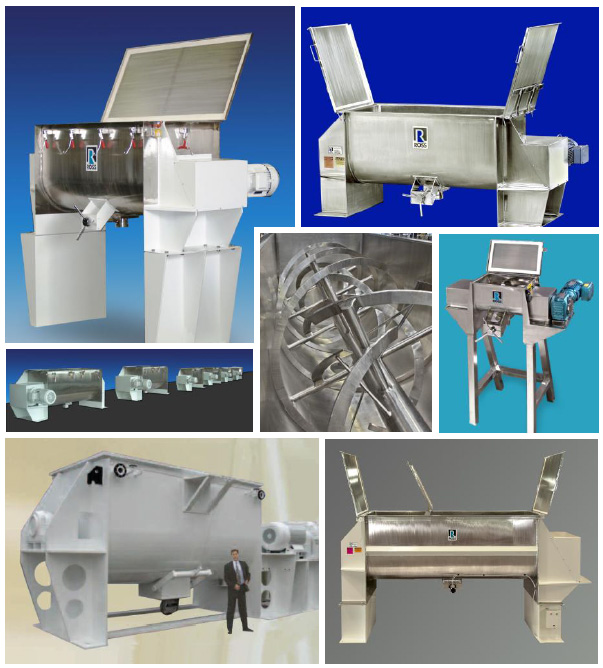

Ross Ribbon Blenders

Ribbon Blenders are well-proven equipment used in batch production of feeds and fertilizers. Ingredients are loaded into the U-shaped trough and mixed by a horizontal solid-shaft agitator consisting of inner and outer helical ribbons. A full load usually corresponds to a product level around the outer ribbon`s tip, allowing enough headroom for the materials to be vigorously agitated. Minor liquid components are typically sprayed at a controlled rate during the blending cycle using atomizing nozzles.

Ross Ribbon Blenders are expertly fabricated to close tolerances to ensure consistent and accurate performance over a long service life. The position and precise pitch of the ribbons produce a well-balanced axial and radial flow pattern, promoting fast and thorough mixing despite differences in particle shape, size and density. Maximum tip speeds in the neighborhood of 300 ft/min are typical but with variable speed control, the blending action can be fine-tuned and optimized according to the characteristics of a particular recipe. When developing a new product, manufacturers can take advantage of trial/rental units prior to scaling up to a production-size Ross Ribbon Blender.

For relatively shear-sensitive compositions, Ross offers gentler mixer alternatives including Cone Screw Vertical Blenders and Tumble Blenders.

Other Applications of Ross Ribbon Blenders:

- Ceramic Powders

- Baking Pre-mixes

- Chemicals

- Coffee Beans

- Cosmetic Powders

- Dental Powders

- Detergents

- Drink Mixes

- Flavorings

- Glass

- Metal Powders

- Pesticides

- Pharmaceuticals

- Refractory Powders

- Soups

- Spices

- Sugars and Sweeteners

- Trail Mix Snacks

- Vitamin Supplements

Advantages of Ross Ribbon Blenders:

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike belt and chain-driven blenders which are noisy and prone to slippage, direct-drive Ribbon Blenders are more reliable and require less maintenance. The cost-effective and space-saving combination of a gearmotor (one-piece motor reducer) and a variable frequency inverter delivers electronic speed control, soft-start capability and overload protection.

- Standard and heavy-duty models are available for accurate sizing according to average bulk density. Capacities range from 1/2 to 1,000 cu.ft.

- Close tolerances between the outer ribbon and trough eliminate dead zones in the batch. Radiused welds, flush valves and polished interior surfaces further prevent caking and material build-up.

- Ross Ribbon Blenders can be customized to incorporate pneumatically-operated covers and discharge valves, bag dump stations, custom ports, interchangeable paddle agitator, spray bar assembly, end wall scrapers, lantern rings, bottom discharge extruder, sanitary features, heating/cooling jacket, load cells and other options to help ensure streamlined processing and fast changeovers.