Tech Report

Recommended Blending Equipment for Cosmetic Powders

Application Summary

Thorough mixing in a well-designed Ribbon Blender is an effective method for preparing face powders, eye shadows, pressed make-up, foundations, blushes, bronzers and other cosmetics supplied in powder form.

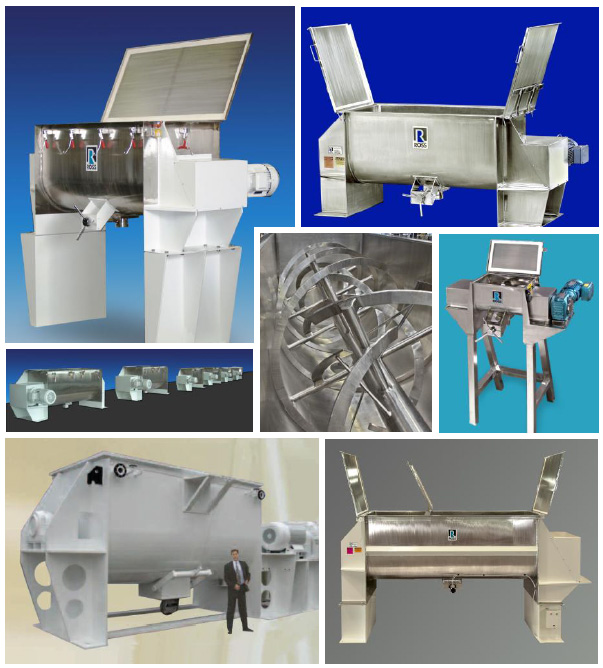

Ross Ribbon Blenders

Ross Ribbon Blenders equipped with horizontal double helical ribbons are well proven in the manufacture of cosmetic powders. Pre-weighed dry raw materials such as talc, mica, silica, stearates, clay, rice starch, zinc oxide, iron oxides, titanium dioxide and various other pigments are loaded into a U-shaped trough. A full load usually corresponds to a product level around the tip of the outer ribbon allowing enough headroom for the materials to be vigorously blended. Any wet ingredients including the liquid binder and perfumes are gradually added to the blend through atomizing spray nozzles. This step is performed as the powders are being agitated to promote uniform coating and prevent the formation of undesired lumps.

The position and precise pitch of each ribbon are designed to produce a well-balanced axial and radial flow pattern: the outer ribbon moves materials in toward the center, and the inner ribbon moves them out toward the walls. At the same time, the difference in the ribbons` speeds causes product to move along the blender`s horizontal axis in two opposite directions. This combination of mixing mechanisms produces a homogenous batch within a short time - in many cases, 15 minutes or less.

Ensuring batch-to-batch integrity and fast changeover, the versatile Ross Ribbon Blender is ideal for high-speed processing of multiple blends having a wide range of bulk densities. With the use of a simple variable frequency drive, agitator speed is easily fine-tuned to match the flow characteristics of a particular recipe at any stage of the blending and discharge cycles.

Other Applications of Ross Ribbon Blenders:

- Advanced Ceramics

- Animal Feeds

- Baking Pre-mixes

- Chemicals

- Coffee Beans

- Cosmetic Powders

- Dental Powders

- Detergents

- Drink Mixes

- Flavorings

- Glass

- Metal Powders

- Pesticides

- Pharmaceuticals

- Refractory Powders

- Soups

- Spices

- Sugars and Sweeteners

- Trail Mix Snacks

- Vitamin Supplements

Advantages of Ross Ribbon Blenders:

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike belt-driven blenders which are noisy and prone to slippage, direct-driven Ribbon Blenders are more reliable and require less maintenance. The cost-effective and space-saving combination of a gearmotor (one-piece motor reducer) and a variable frequency inverter delivers electronic speed control, soft-start capability and overload protection.

- Different duty models are available for accurate sizing according to average bulk density. Standard capacities range from 1/2 to 1,000 cu.ft.

- Ross Ribbon Blenders are fabricated to close tolerances for accurate mixing. Clearances between the agitator and the trough surfaces typically fall between 1/8" and 3/16". This enhances mixing performance by preventing materials from stagnating in any part of the blender.

- Stainless steel surfaces are polished to 60-grit finish and each weld is "radiused" for easy cleanability. Optional higher grit finishes also supplied.

- Popular customizations include pneumatically-operated covers and discharge valves, bag dump stations, custom ports, liquid spray bar, load cells, high speed choppers, heating/cooling jacket, vacuum construction, operator stations and PLC recipe controls.