Tech Report

Recommended Blending Equipment for Baking Mixes

Application Summary

Mixes for breads, cakes, cookies, muffins, biscuits, waffles, brownies and other baked goods demand a high level of accuracy. Ingredients such as flour, baking soda, sugar, milk powder, starch, yeast, salt, gums, flavors and additives are combined in a precise proportion which must be preserved in the final packaging.

Thorough mixing in a well-designed Ribbon Blender is a reliable method for preparing baking mixes with superior batch-to-batch consistency and minimal downtime between recipes.

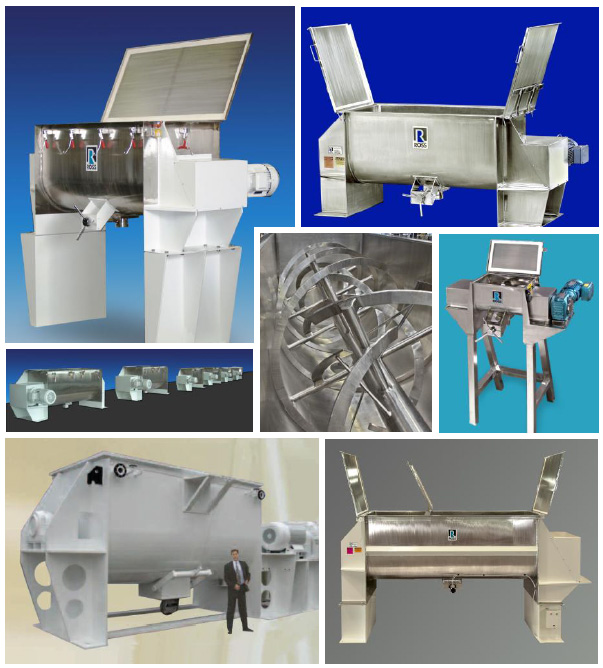

Ross Ribbon Blenders

The Ribbon Blender is well-proven technology for cost-effective and accurate mixing of baking mixes. Dry ingredients are loaded into the U-shaped trough and mixed by a horizontal solid-shaft agitator consisting of inner and outer helical ribbons. The position and precise pitch of each ribbon produce a well-balanced axial and radial flow pattern, promoting fast and thorough mixing even of very minor ingredients. If present, liquid components are sprayed into the powders at a controlled rate to evenly coat the solid particles as they are being mixed vigorously.

Maximum tip speed of the ribbon agitator is around 300 ft/min. Utilizing a Variable Frequency Drive (VFD), the blending action can be fine-tuned according to the characteristics of a particular recipe, i.e. its density, flowability, tendency to dust, presence of large or fragile particles, etc. The advantage of electronic speed control is significant especially for plants that batch multiple products in one blender. Designed to handle fast-paced and frequent changeovers, Ross Ribbon Blenders are also extensively used for mixing flour blends, spices, sweeteners, bread improvers and other baking ingredients.

As the world`s largest manufacturer of Ribbon Blenders, Ross supplies to hundreds of food companies, flavor houses, toll manufacturers, commercial bakeries, gourmet food stores, food laboratories and raw material suppliers.

Other Applications of Ross Ribbon Blenders:

- Advanced Ceramics

- Animal Feeds

- Baking Pre-mixes

- Chemicals

- Coffee Beans

- Cosmetic Powders

- Dental Powders

- Detergents

- Drink Mixes

- Flavorings

- Glass

- Metal Powders

- Pesticides

- Pharmaceuticals

- Refractory Powders

- Soups

- Spices

- Sugars and Sweeteners

- Trail Mix Snacks

- Vitamin Supplements

Advantages of Ross Ribbon Blenders:

- Direct drive design is standard on all Ross Ribbon Blenders. Unlike belt-driven blenders which are noisy and prone to slippage, direct-driven Ribbon Blenders are more reliable and require less maintenance. The cost-effective and space-saving combination of a gearmotor (one-piece motor reducer) and a variable frequency inverter delivers electronic speed control, soft-start capability and overload protection.

- Interior stainless steel surfaces are polished and each weld is "radiused" for easy cleanability. In addition to tightly-controlled clearances between the agitator and trough, end wall scrapers can be supplied for highly sensitive applications to further prevent "dead zones" where product can collect.

- Different duty models are available for accurate sizing according to average bulk density. Standard capacities range from 1/2 to 1,000 cu.ft.

- Ross Ribbon Blenders can be customized to incorporate pneumatically-operated covers and discharge valves, bag dump stations, custom ports, interchangeable paddle agitator, liquid spray bar, load cells, high speed choppers, rotary CIP spray balls, PLC recipe systems and other accessories to help ensure streamlined ingredient transfers, efficient discharge and fast changeovers.