Tech Report

Recommended Blending and Drying Equipment for Ceramic Powders and Slurries

Application Summary

Ceramic powders that need to be mixed with other solids or coated with a liquid prior to drying are efficiently processed in a Vertical Blender/Dryer.Manufacturers benefit from the ability of the VerticalBlender/Dryer to quickly remove moisture or solvent from a wide range of feed forms- from slurries and pastes to granules, pellets and powders.This technology is also highly considered for ceramic applications where spray drying is extremely impractical in terms of high energy, pressure or maintenance requirements.

Ross Vertical Blender/Dryers

Ross Vertical Blender/Dryers are ideal for blending and drying ceramic materials whether in powder or slurry form. These machines feature a slow turning auger screw that orbits around a conical vessel. As it turns, the screw gently lifts material upward and towards the center of the batch. Product from the top cascades back to the bottom while mixing with material being moved upward by the orbiting screw. This agitation mechanism is very thorough yet imparts minimal wear making it suitable even for abrasive applications like silicon carbide and zirconium oxide. Unlike blenders that operate using a rotating vessel, the Vertical Blender is not sensitive to order of addition, positioning of raw materials and fill level. It also allows operators to add raw materials in stages or increments without having to stop the blender.

As opposed to conventional ovens and tray dryers where product is stationary, the layer of material contacting the Vertical Blender/Dryer`s heated sidewalls is constantly being renewed. Under vacuum conditions, the continuous but gentle turnover of materials accelerates drying, generally without affecting bulk density or generating fines. At the end of the drying cycle, the finished product is quickly and completely discharged out of the steeply angled conical vessel.

How a Vertical Blender/Dryer works:

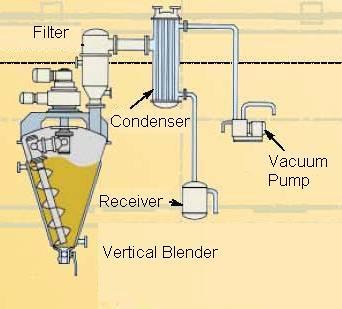

Heat is applied to the jacketed vessel of the vertical blender.Once vacuum is established, the combination of low absolute pressure, gentle heat and slow agitation quickly forces moisture from the bulk material. Vapors generated in the process pass through a filter and into a condenser. A receiver collects the condensed liquid for proper disposal or re-use, if applicable.

Other Applications ofRoss Vertical Blender/Dryers:

- Beverages

- Botanical Extraction

- Ceramic Powders

- Chemicals

- Detergents

- Fertilizers

- Fillers

- Foods

- Glass

- Herbicides

- Lubricants

- Microspheres

- Nutritional Supplements

- Pharmaceuticals

- Pigments

- Wood Fibers

Benefits of Ross Vertical Blender/Dryers

- Fully top-supported screw agitator. Without a bottom support bearing to get in the way, the blended batch is discharged quickly and completely. This design also allows the machine to be operated with very little maintenance.

- Many standard sizes. Standard models from 1 to 500-cu.ft. working capacity can be designed for a specific bulk density range.

- Smaller footprint compared to other types of blenders and dryers.

- Highly effective moisture removal. Ross Vertical Blender/Dryers are commonly used for vacuum drying materials to less than 0.10% moisture.

- Low energy consumption and fast drying rates.

- Customers can rely on Ross for customizations and auxiliary equipment, including internal pressure construction, pneumatically operated valves, custom ports and manways, inert gas injection nozzles, load cells, temperature probes, heating units, vacuum pumps and controls ranging from simple Variable Frequency Drives and operator stations to more sophisticated PLC`s and HMI`s.