Tech Report

Improve emulsion stability through ultra-high shear mixing

Technology Brief

The droplet size distribution of an emulsion largely dictates its stability. Fine droplet sizes are produced by applying sufficient shear, often through the use of conventional rotor/stator mixers. Today, ultra-high shear rotor/stator designs are available which can improve emulsion stability of certain formulations.

High shear mixing and emulsification

Throughout the process industries, rotor/stator mixers are widely used in the preparation of emulsions - from cosmetic creams to pressure-sensitive adhesives and specialty coatings. Available in batch or inline configurations, these mixers are comprised of a rotor that turns at high speed within a stationary stator. As the blades rotate, materials are continuously drawn into one end of the mixing head and expelled at high velocity through the openings of the stator. The hydraulic shear promotes fast mixing and reduces the size of droplets in emulsions. Rotor tip speeds between 3,000 to 4,000 ft/min are typical.Droplet size dictates emulsion stability

In a stable emulsion, the dispersed phase is suspended uniformly as droplets throughout the continuous phase, the two phases immiscible with each other. Big and small drops coexist in the emulsion and their size distribution gives the best description of the emulsion, affecting both stability and viscosity. The length of time in which a considered stable emulsion does not change its aspect is relative. For instance, a storage stability period of a few years is reasonable to expect for a medical ointment.

For emulsification to take place and remain stable, sufficient mixing energy is required. Generally, the higher the shear put into creating the emulsion, the finer the droplets produced, and the more stable the emulsion. However, some emulsions are shear-sensitive such that droplets start to coalesce beyond a certain level of shear. Of course, many other factors apart from shear input affect emulsion stability including inherent properties of the dispersed phase and the continuous phase, temperature, presence and type of surfactant, etc. In other words, the "ideal" average drop size varies from one formulation to another.

Equilibrium droplet size

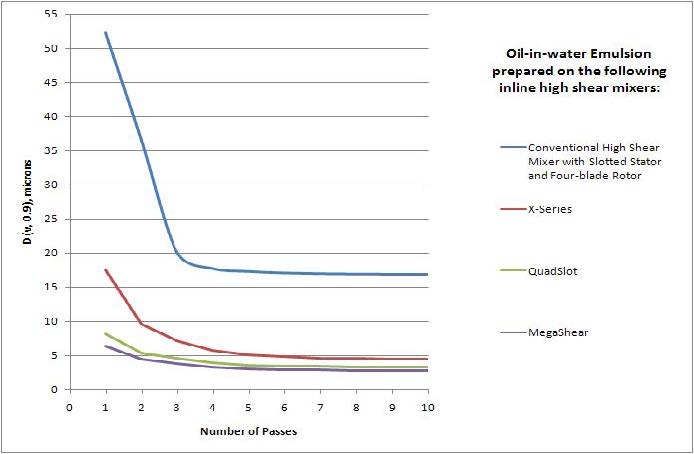

In an inline rotor/stator mixer, the greatest extent of droplet size reduction typically occurs within the first few passes. This phenomenon is true for almost any emulsion. Past this stage of sharp decrease in droplet size, the emulsion hovers at an equilibrium size despite subsequent recirculation. The same trend applies to batch rotor/stator mixing systems although the actual number of product turnovers is not as easy to define. It`s always useful to know the point at which droplet size is already in equilibrium in order to avoid over-processing. Over-processing not only unnecessarily consumes time and power, but may also heat the emulsion causing droplets to recombine or induce an irreversible change in viscosity.

Ultra-high shear mixing

If the equilibrium droplet size achieved in a conventional rotor/stator is larger than desired, switching to a higher energy mixer design is recommended. Charles Ross & Son Company offers the X-Series, QuadSlot and MegaShear ultra-high shear mixers for products that traditional rotor/stators cannot process adequately. Ultra-high shear mixers operate at higher tip speeds than conventional rotor/stators, around 11,000 - 18,000 fpm. Product is subjected to higher levels of shear and more complex turbulent mixing patterns. As a result, ultra-high shear mixers can finish certain emulsions with lower surfactant loadings than previously required. In certain applications, they can also replace colloid mills and high pressure homogenizers, often delivering higher throughput while requiring less maintenance.

Ross Inline Ultra-High Shear Mixers

X-Series

The X-Series head consists of concentric rows of intermeshing teeth. Product enters at the center of the stator and moves outward through radial channels in the rotor/stator teeth. The combination of high tip speed and extremely close tolerances subjects the product to intense shear in every pass. The gap between adjacent surfaces of the rotor and stator is adjustable for fine-tuning shear levels and flow rates.

QuadSlot

The QuadSlot mixing head is a multi-stage rotor/stator with a fixed clearance. This generator produces higher pumping rates and requires higher horsepower compared to an X-Series rotor/stator set running at similar speeds.

MegaShear

The MegaShear operates at the same tip speed as the X-Series and QuadSlot heads, but is even more aggressive in terms of shear and throughput levels. It consists of parallel semi-cylindrical grooves in the rotor and stator towards which product is forced by high velocity pumping vanes. Different streams are induced within the grooves and collide at high frequency before exiting the mix chamber.

Comparison of droplet size reduction performance

The above graph shows droplet size curves for an oil-in-water emulsion prepared in a conventional high shear mixer and in the X-Series, QuadSlotand MegaShear ultra-high shear mixers.