Tech Report

Extremely viscous mixtures

Technology Brief

Kneaders are well proven and reliable mixers employed in the compounding of extremely viscous mixtures that cannot be processed efficiently in vertical-style agitators such as double planetary mixers.

Vertical vs. horizontal mixing of viscous applications

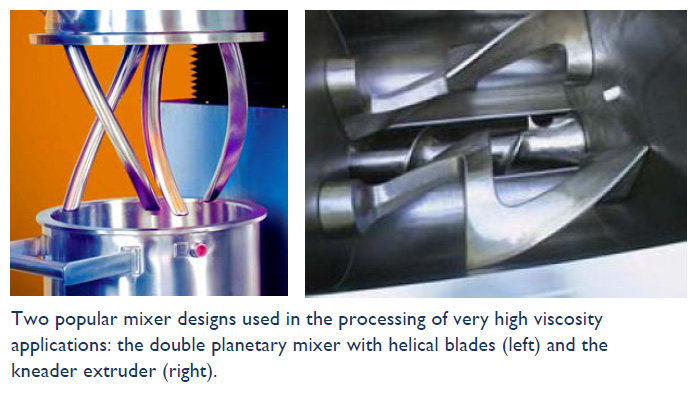

Among the variety of vertical mixing systems, the heavy-duty double planetary mixer offers the best capability in terms of thorough agitation and heat transfer at very high viscosity levels. In particular, Ross Double Planetary Mixers equipped with the patented High Viscosity "HV" Blades can handle formulation sup to 6 million cP or greater. The HV planetary blades prevent the `climbing` problem commonly experienced with traditional rectangular stirrers. Their precisely angled helical contour generates a unique mixing action: as the blades orbit around the vessel while rotating on their own axis, each sweeping curve firmly pushes batch material forward and downward, keeping it within the mixing zone at all times. Superior top-to-bottom mixing is easily accomplished, even in very thick and dense materials.

The advantages of vertical mixers - wherein agitators enter from the top of atypically interchangeable mix vessel - over horizontal fixed-trough mixers generally include lower capital cost, smaller footprint, reduced energy consumption and easier maintenance.

However, horizontal kneaders and kneader extruders remain to be the most powerful equipment utilized for extremely viscous formulations. Manufacturers can potentially benefit from looking into double planetary mixing if they stayed with a classic kneader simply because it was an inherited process. But there are a number of applications that can only be handled using horizontal kneaders.

A kneader, also called a double arm sigma blade mixer, is composed of two z-shaped blades that rotate toward each other at differential speeds. The blades pass the trough walls and each other at close clearances, providing a shearing and tearing action on the product being mixed. At the end of the cycle, the trough of the mixer is tilted and the finished product is discharged for transfer to a downstream operation. The kneader extruder combines the efficiency of a conventional double arm sigma blade mixer with the convenience of an extrusion screw for discharging heavy and viscous materials. This discharge screw is located in a separate cavity just below the z-blades and helps feed batch material into the mixing blades. Once the mixing/kneading cycle is complete, the screw extrudes the product out through a discharge opening or die.

Sample kneader extruder application

The following sequence describes a typical manufacturing process of a hot melt pressure sensitive adhesive in a Ross/AMK Kneader Extruder. The mixing trough and extrusion barrel are jacketed for hot oil or steam heating.

Thermoplastic rubber and low-melting point tackifying resins are added to the kneader extruder. As the solid rubber and resins melt, the batch knits together and begins to form into a viscous mass.

All the low-melting point ingredients are completely melted and kneaded between the blades for some time. This is followed by the addition of high melting point resins and further mixing.

When all the solids are melted and thoroughly blended in, plasticizer oil is added at a controlled rate to slowly lower the viscosity. The extrusion screw is then reversed and the product is extruded through the discharge adaptor. The finished batch is a homogeneous adhesive over 10 million cP.