Tech Report

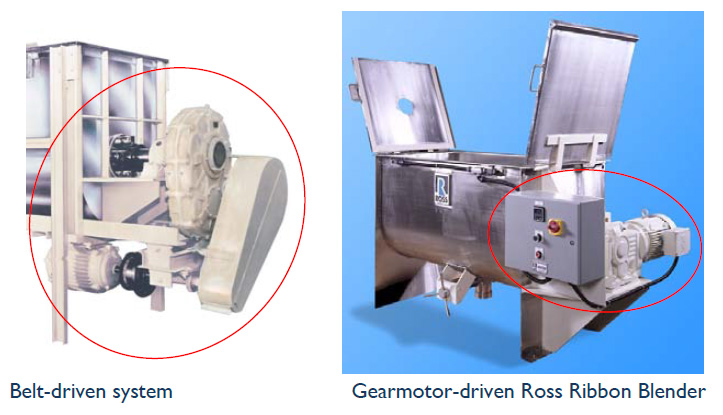

Direct drive ribbon blenders offer better operating efficiency and performance compared to belt-driven designs.

Technology Brief

Traditional belt-driven ribbon blenders are prone to slippage and suffer from subsequent losses in efficiency and production. Direct drive ribbon blenders equipped with gear motors are more reliable, delivering better performance and requiring less maintenance. Because gear motors are designed to work well with inverters, users benefit from electronic speed control, soft-start capabilities and overload protection.

Gearmotors vs. belt drives

Ribbon blenders have traditionally incorporated a belt drive for power transmission between the motor and gear reducer. The drive system includes flexible belts and a set of pulleys to help produce the desired speed and torque ranges. Some manufacturers standardize on chain drives instead of belts.

A gearmotor, on the other hand, is a one-piece motor reducer. The motor`s low inertia rotor is specifically matched to the characteristics of the gear unit. This results in a high dynamic capability essential for high start/stop cycles such as ribbon blending operations. Gearmotors are also designed to work well with electronic inverters. This combination in a direct drive ribbon blender provides enhanced speed control and features such as overload protection and adjustable starting torques.

Practical advantages of direct drive ribbon blenders

Belt-driven ribbon blender systems suffer from losses in horsepower and efficiency through belt slippage. Belts also impose overhung loads which can limit the longevity of motor/reducer bearings. Their limited flexibility typically cannot accommodate high start/stop blending cycles. Belts "stretch" during their life especially when new so a ribbon blender system would require tension adjustment when first installed and as the belt wears or stretches.

By comparison, modern gearmotors deliver higher operating efficiency, better performance and numerous practical advantages. Because overhung loads on the motor and reducer-shaft bearings are eliminated in gearmotors, service life is longer. Maintenance required to align and adjust belts and couplings is eliminated as well. Today`s compact gearmotor designs enable smaller mounting platforms which improve the ribbon blender`s overall space requirement.

Soft start and speed flexibility

Manufacturers used to rely on belt-driven systems equipped with soft start couplings for high "dead load" starting situations. Shot-filled couplings were prone to overheating which ruined the coupling. Hydraulic couplings followed and with a fail-safe fuse, the hydraulic drive can at least be re-used after an overload. Either coupling design however drives up the blender cost and adds an extra maintenance-requiring element.

The evolution of gearmotor design, in combination with today`s latest electronic drive technology, opens up possibilities that were simply not available in past blender designs. Variable frequency drives (VFD) allow soft start and provide a convenient way of controlling speed anytime during blending and discharging. For most ribbon blender applications, gearmotor/VFD technology is the most reliable and cost-effective option. Sophisticated PLC systems can be easily integrated to program various steps and recipes in more demanding processes.

Sample Installation

A major petro chemical company operates thirty two(32) 515-cu.ft. direct driveRoss Ribbon Blenders for large-scale blending and heating of specialty chemical powders supplied to the oil drilling industry. The gearmotors in these giant and robust blenders help make them extremely reliable and easy to maintain.