Tech Report

Blending abrasive solids

Technology Brief

Solid blends containing abrasive particles may be processed in a ribbon blender, vertical cone screw blender or tumble blender. The advantages and disadvantages of these blender designs are discussed in this bulletin, as well as some strategies for combating abrasive wear.

Solids blending equipment

Three of the most commonly used solid-solid mixing equipment today are the horizontal ribbon blender, vertical cone screw blender and tumble blender. Any of these blenders are suitable for blending abrasive applications. Each design presents its own advantages and disadvantages which are discussed below.

Ribbon blender

A ribbon blender consists of a U-shaped horizontal trough and an agitator made up of inner and outer helical ribbons that are pitched to move material axially in opposite directions, as well as radially. The ribbons rotate with tip speeds of approximately 300 fpm. An interchangeable paddle-style agitator may be supplied on this type of blender.

Due to its versatility and economy, the ribbon blender is often the best choice for most mainstream blending applications. When abrasive solids are involved, the trough and agitator may be constructed from abrasion-resistant steel that is compatible with the product being blended. Installing a paddle agitator is another option as it has less surface area at the periphery than a ribbon agitator and thus generates lower shear.

Normally, the agitator shaft is sealed with packing materials to prevent product from getting into the stuffing box. If abrasive powders are left unchecked and allowed to invade the stuffing box, they can grind the shaft away and cause premature wear. Purged stuffing boxes are highly recommended when dealing with abrasive or fine powder applications. Air enters the seal through "lantern rings" and provides positive pressure to prevent intrusion of particles.

Vertical cone screw blender

A vertical blender features a slow turning auger screw which orbits a conical vessel wall while it turns and gently lifts material upward. As materials reach the upper most level of the batch, they cascade slowly back down in regions opposite the moving auger screw. This blending action imparts significantly less shear than a ribbon or paddle blender and generates less friction on the agitator and vessel wall surfaces, making it ideal for most abrasive applications. For added protection against wear, product-contacting moving parts of the vertical blender (i.e. auger screw and discharge valve) may be hard chrome plated.

A critical design feature that must be considered, for any application but most especially when handling abrasives, is a fully top-supported auger screw. The absence of a bottom support bearing in a vertical blender is important because it facilitates complete discharge, simplifies cleaning and reduces contamination risks.

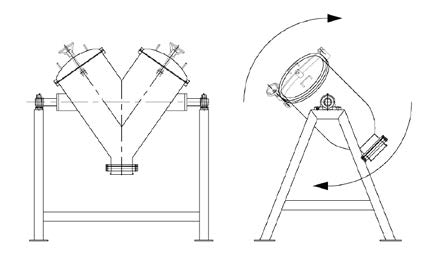

Tumble blender

A tumble blender is a rotating device that commonly comes in V-shaped or double-cone configurations.Operating speeds in the range of 5to 25 revolutions per minute are typical. Materials cascade and intermix as the vessel rotates. This mixing mechanism is very low-impact and appropriate for processing abrasive solids.Like the vertical blender, the tumble blender is capable of 100% discharge due to its geometry. It does however require a large footprint to accommodate the mixer base, as well as ample overhead space for the vessel to rotate.

Sample Application: Crushed Glass

A Ross Tumble Blender installed at a solar cell manufacturing facility is being used to blend crushed glass and mineral powders for a proprietary formulation.